ʻOihana Hoʻokele Lako, Sinopec Yizheng Chemical Fiber Co., Ltd. 211900

ʻĀpana: Ke kālailai nei kēia pepa i nā kumu ʻino o nā ʻāpana turbo expander nui, hoʻopuka i nā ʻano hana e hoʻoponopono ai i nā pilikia, a hopu i nā wahi pilikia a me nā ana pale o ka hana.Ma o ka hoʻohana ʻana i ka ʻenehana hoʻoneʻe varnish, hoʻopau ʻia nā pōʻino huna huna a hōʻoia ʻia ka palekana o ka ʻāpana.

1. ʻike

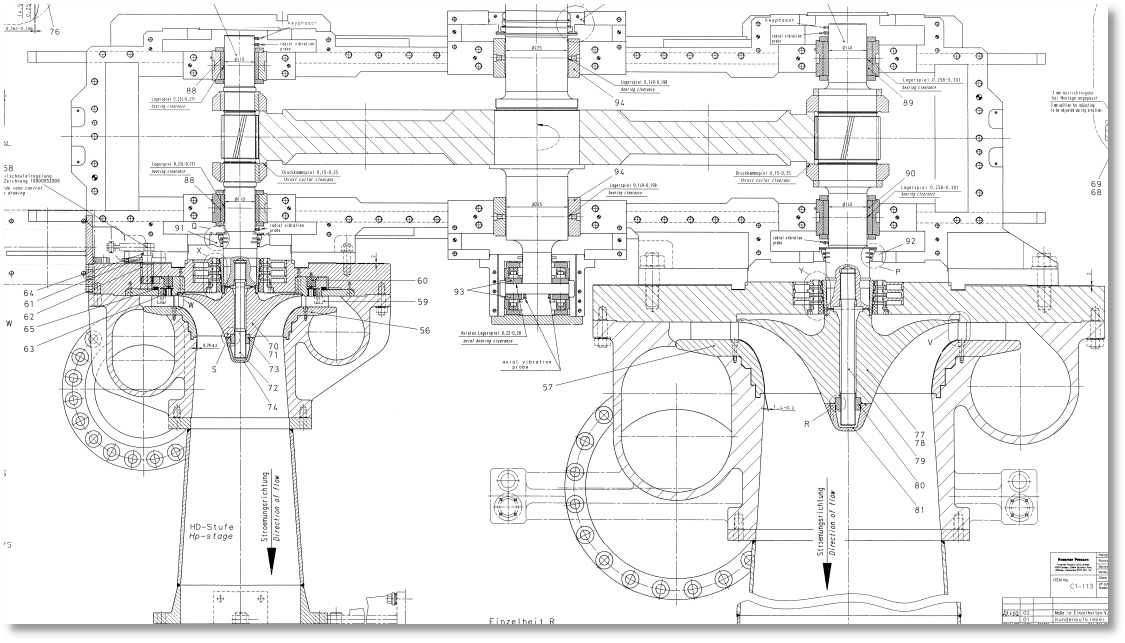

ʻO ka pūʻulu hoʻoheheʻe ea o ka 60 t/a PTA mea kanu o Yizheng Chemical Fiber Co., Ltd. ua lako me nā lako mai Germany MAN Turbo.ʻO ka ʻāpana he ʻekolu-i-hoʻokahi ʻāpana, kahi i hoʻohana ʻia ai ka mīkini hoʻoheheʻe ea he multi-shaft five-stage turbine unit, ka condensing steam turbine i hoʻohana ʻia e like me ka mīkini hoʻokele nui o ka ea compressor unit, a ʻo ka turbo expander. hoʻohana ʻia e like me ka ea compressor unit.Mīkini hoʻokele kōkua.Hoʻohana ka turbo expander i ka hoʻonui kiʻekiʻe a me ka haʻahaʻa haʻahaʻa ʻelua, loaʻa i kēlā me kēia me kahi port suction a me kahi port exhaust, a hoʻohana ka impeller i kahi impeller ʻekolu ala (e nānā i ke Kiʻi 1)

Kiʻi 1 Nānā ʻāpana o ka ʻāpana hoʻonui (hema: ʻaoʻao kaomi kiʻekiʻe; ʻākau: ʻaoʻao kaomi haʻahaʻa)

ʻO nā ʻāpana hana nui o ka turbo expander penei:

ʻO ka wikiwiki o kaʻaoʻao kiʻekiʻe he 16583 r / min, aʻo ka wikiwiki o kaʻaoʻao haʻahaʻa he 9045 r / min;ʻO ka mana piha o ka mea hoʻonui i helu ʻia ʻo 7990 KW, a ʻo ka kahe kahe o 12700-150450-kg / h;ʻO ke kaomi inlet he 1.3Mpa, a he 0.003Mpa ke kaomi hoʻopau.ʻO ka mahana hoʻokomo o ka ʻaoʻao kiʻekiʻe ʻo 175 ° C, a ʻo ka wela wela he 80 ° C;ʻO ka mahana hoʻokomo o ka ʻaoʻao haʻahaʻa haʻahaʻa he 175 ° C, a ʻo ka mahana wela he 45 ° C;Hoʻohana ʻia kahi hoʻonohonoho tilting pads ma nā ʻaoʻao ʻelua o ka ʻaoʻao kiʻekiʻe a me ka haʻahaʻa haʻahaʻa ʻaoʻao gear shafts Bearings, kēlā me kēia me 5 pads, hiki i ka pipeline inlet aila ke komo i ka aila ma nā ala ʻelua, a ʻo kēlā me kēia bearing he hoʻokahi puka ʻaila, ma o 3 mau pūʻulu o 15 aila injection nozzles, ke anawaena o ka aila inlet nozzle he 1.8mm, Aia 9 aila hoʻihoʻi puka no ka bearing, a ma lalo o nā kūlana maʻamau, 5 mau awa a me 4 mau poloka.Hoʻohana kēia ʻekolu-i-hoʻokahi i ke ʻano lubrication ikaika o ka hoʻolako ʻana i ka aila kikowaena mai ka hale ʻaila lubricating.

2. Pilikia me na ohua

I ka makahiki 2018, i mea e hoʻokō ai i nā koi hoʻokuʻu VOC, ua hoʻohui ʻia kahi ʻāpana VOC hou i ka mea hana e mālama i ke kinoea huelo o ka reactor oxidation, a ua hoʻokomo ʻia ke kinoea huelo i mālama ʻia i ka expander.No ka mea, ua oxidized ka paʻakai bromide i loko o ke kinoea huelo kumu i ka wela kiʻekiʻe, aia nā ion bromide.I mea e pale aku ai i nā ion bromide mai ka condensing a me ka hoʻokaʻawale ʻana i ka wā e hoʻonui ai ke kinoea huelo a hana i loko o ka expander, e hana ia i ka corrosion pitting i ka expander a me nā mea hana ma hope.No laila, pono e hoʻonui i ka mea hoʻonui.ʻO ka wela hoʻokomo a me ka wela wela o ka ʻaoʻao kiʻekiʻe a me ka ʻaoʻao haʻahaʻa (e nānā i ka Papa 1).

Papa 1 Ka papa inoa o nā mahana hana ma ka puka komo a me ka puka o ka mea hoʻonui ma mua a ma hope o ka hoʻololi ʻana o VOC

| ʻAʻOLE. | Hoʻololi ʻāpana | Ka hoololi ana o ka mua | Ma hope o ka hoʻololi ʻana |

| 1 | Pumi kiʻekiʻe ʻaoʻao intake ea wela | 175 °C | 190 °C |

| 2 | Pumi kiʻekiʻe ʻaoʻao exhaust wela | 80 ℃ | 85 °C |

| 3 | Haʻahaʻa kaomi ʻaoʻao intake ea wela | 175 °C | 195 °C |

| 4 | Pumi haʻahaʻa ʻaoʻao hoʻopau wela | 45 °C | 65 °C |

Ma mua o ka hoʻololi ʻana o VOC, ua kūpaʻa ka mahana o ka ʻaoʻao non-impeller i ka hopena haʻahaʻa haʻahaʻa ma kahi o 80 ° C (ʻo 110 ° C ka mahana wela o ka bearing ma aneʻi, a ʻo 120 ° C ka mahana wela).Ma hope o ka hoʻomaka ʻana o ka hoʻololi ʻana o VOC ma Ianuali 6, 2019, ua piʻi mālie ka mahana o ka ʻaoʻao non-impeller i ka hopena haʻahaʻa o ka expander, a ua kokoke ka wela kiʻekiʻe loa i ka wela i hōʻike ʻia he 120 ° C, akā ʻo ka ʻAʻole i loli nui nā ʻāpana haʻalulu i kēia manawa (e nānā i ke Kiʻi 2).

Fig. 2 Diagram of expander flow rate and non-drive side shaft vibration and temperature

1 - laina kahe 2 - laina hope ʻole kaʻa ʻole 3 - laina haʻalulu ʻaʻole kaʻa

3. Ka nānā 'ana i ke kumu a me ke 'ano o ka mālama 'ana

Ma hope o ka nānā ʻana a me ka nānā ʻana i ke ʻano o ka hoʻololi ʻana o ka wela o nā bearings turbine, a me ka hoʻopau ʻana i nā pilikia o ka hōʻike ʻana i nā mea kani ma ka pūnaewele, ka hoʻololi ʻana o ke kaʻina hana, ka hoʻoili ʻana o ka ʻaʻahu pahu turbine mahu, nā loli wikiwiki o nā mea hana, a me nā ʻāpana maikaʻi, nā kumu nui o ka lawe ʻana i ka wela. he:

3.1 Nā kumu no ka piʻi ʻana o ka wela o ka ʻaoʻao non-impeller e kau ana ma ka hopena haʻahaʻa o ka mea hoʻonui.

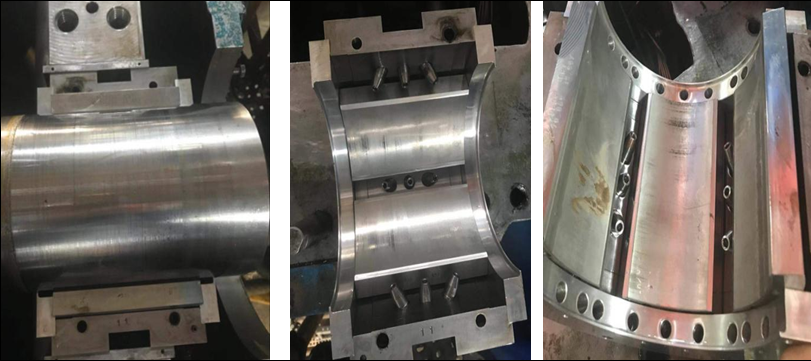

3.1.1 Ua ʻike ʻia ka nānā ʻana o ka wehe ʻana i ka mamao ma waena o ka bearing a me ke kumu a me ka hoʻomaʻemaʻe ʻana o nā niho niho.Koe wale no ka varnish i manaʻo ʻia ma ka ʻaoʻao non-impeller e hali ana i ka ʻili ma ka hopena haʻahaʻa haʻahaʻa o ka mea hoʻonui (e nānā i ke Kiʻi 3), ʻaʻohe mea ʻino i loaʻa i nā bearings ʻē aʻe.

Kiʻi 3 ʻO ke kiʻi kino o ka mea hoʻopau hope ʻole a me ka hui kinematic o ka mea hoʻonui

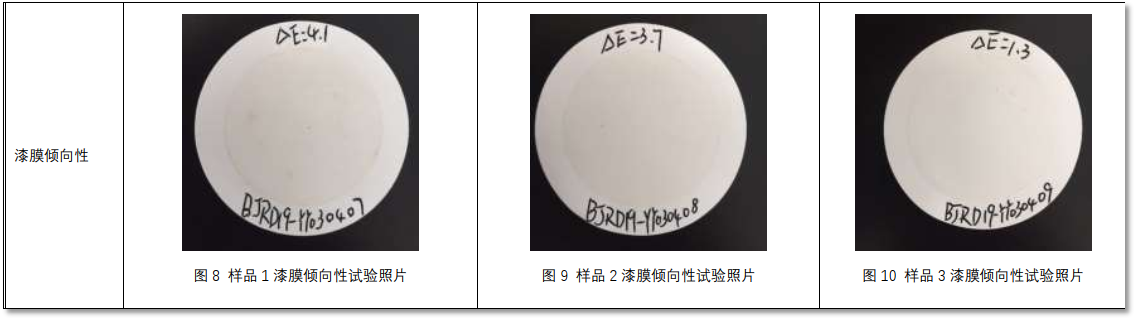

3.1.2 No ka mea ua hoʻololi ʻia ka ʻaila lubricating no ka liʻiliʻi o hoʻokahi makahiki, ua hala ka maikaʻi o ka ʻaila i ka hoʻāʻo ma mua o ka hoʻokele.I mea e hoʻopau ai i nā kānalua, ua hoʻouna ka hui i ka ʻaila lubricating i kahi hui ʻoihana no ka hoʻāʻo a me ka nānā ʻana.Ke hōʻoia nei ka ʻoihana ʻoihana ʻo ka hoʻopili ʻana ma ka ʻaoʻao bearing he varnish mua, MPC (varnish propensity index) (e nānā i ke kiʻi 4)

Kiʻi 4 Hōʻike loiloi ʻenehana nānā ʻaila i hoʻopuka ʻia e ka ʻenehana ʻoihana nānā ʻaila

3.1.3 ʻO ka ʻaila lubricating i hoʻohana ʻia i ka expander ʻo Shell Turbo No. 46 turbine oil (mineral oil).Ke loaʻa ka ʻaila mineral i kahi wela kiʻekiʻe, ua hoʻoheheʻe ʻia ka ʻaila lubricating, a hōʻiliʻili nā huahana oxidation ma ka ʻili o ka lāʻau bearing e hana i kahi varnish.ʻO ka aila lubricating mineral ka mea nui i nā mea hydrocarbon, kahi paʻa i ka lumi wela a me ka wela haʻahaʻa.Eia nō naʻe, inā loaʻa kekahi (he helu liʻiliʻi loa) o nā molekala hydrocarbon i nā hopena oxidation ma nā wela kiʻekiʻe, e loaʻa pū kekahi mau molekala hydrocarbon ʻē aʻe i nā hopena kaulahao, ʻo ia ke ʻano o nā hopena o ke kaulahao hydrocarbon.

3.1.4 Ua hana nā ʻenehana mea hana i nā noiʻi e pili ana i ke kākoʻo o ke kino mea hana, ke koʻikoʻi anuanu o nā pipeline inlet a me waho, ka ʻike leak o ka ʻōnaehana ʻaila, a me ka pololei o ka ʻimi wela.A ua hoʻololi i kahi hoʻonohonoho o nā bearings ma ka hopena non-drive o ka ʻaoʻao haʻahaʻa haʻahaʻa o ka expander, akā ma hope o ka hoʻokele ʻana no hoʻokahi mahina, hiki i ka mahana ke hiki i 110 ℃, a laila ua nui nā fluctuations i ka vibration a me ka mahana.Ua hana ʻia kekahi mau hoʻololi i mea e hoʻokokoke ai i nā kūlana pre-retrofit, akā aneane ʻaʻohe hopena (e nānā i ke Kiʻi 5).

Kiʻi 5 Ka pakuhi au o nā hōʻailona pili mai Pepeluali 13 a Malaki 29

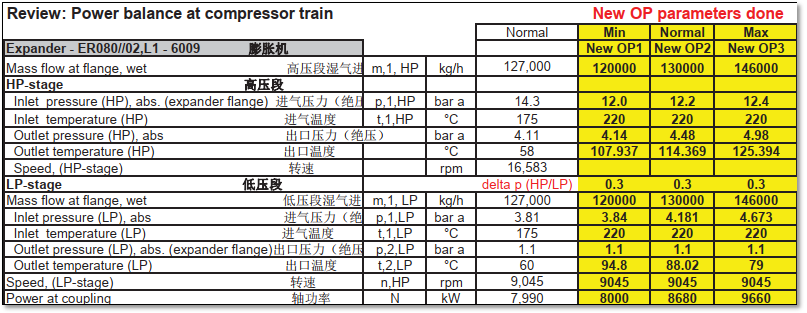

ʻO ka mea hana MAN Turbo, ma lalo o nā kūlana hana o kēia manawa o ka expander, inā paʻa ka nui o ka ea intake ma 120 t / h, ʻo ka mana hoʻopuka he 8000kw, kahi kokoke loa i ka mana hoʻolālā kumu o 7990kw ma lalo o nā kūlana hana maʻamau;Ke 1 30 t/h ka nui o ka ea, 8680kw ka mana puka;inā he 1 46 t/h ka nui o ka ea intake, he 9660kw ka mana puka.No ka mea, ʻo ka hana i hana ʻia e ka ʻaoʻao haʻahaʻa haʻahaʻa he ʻelua hapakolu o ka mea hoʻonui, hiki ke hoʻonui ʻia ka ʻaoʻao haʻahaʻa o ka mea hoʻonui.Ke piʻi ka mahana ma mua o 110 °C, hoʻololi nui ka waiwai vibration, e hōʻike ana i ka varnish i hana hou ʻia ma ka ʻili o ka lāʻau a me ka lāʻau bearing i kēia wā (e nānā i ke Kiʻi 6).

Kiʻi 6 Pākaukau kaulike mana o ka ʻāpana hoʻonui

3.2Ka Hana Hana Hana o na pilikia e ku nei

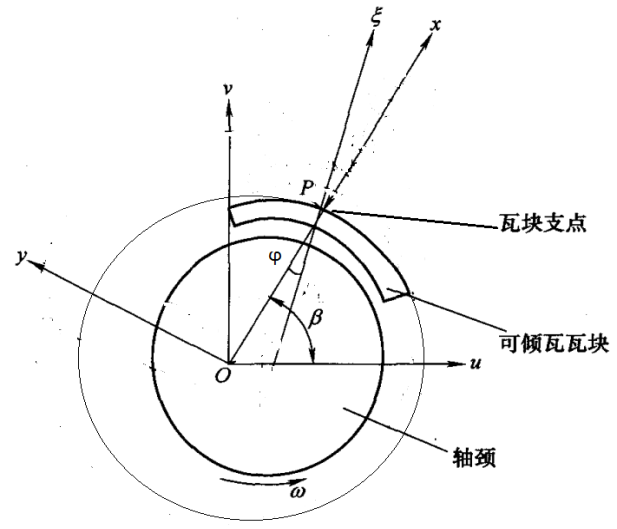

3.2.1 E like me ka mea i hoikeia ma ke Kii 7, hiki ke ike ia ka huina i komo ma waena o ke kuhikuhi haalulu iki o ka fulcrum o ka poloka tile a me ka laina hookuonoono i ka papa kuhikuhiE β , o ka huina kowali o ka poloka tile he φ. , a me ka tilting pad bearing system i hakuia me 5 tiles, i ka wa o ka tile I ka wa e kau ai ka pad i ka aila film pressure, no ka mea, aole he kino paa loa ka fulcrum o ka pad, ke kulana o ka fulcrum of the pad after compression deformation. hana i kahi neʻe liʻiliʻi ma ka ʻaoʻao preload geometric ma muli o ka ʻoʻoleʻa o ka fulcrum, a laila e hoʻololi ai i ka ʻae ʻana o ka bearing a me ka mānoanoa kiʻi ʻaila [1] .

Fig.7 Pūnaehana hoʻonohonoho o ka papa hoʻokahi o ke kuʻekuʻe wāwae

3.2.2 Hiki ke ʻike ʻia mai ka Figure 1 ʻo ka rotor he ʻano hoʻolālā cantilever beam, a ʻo ka impeller ka mea hana nui.No ka mea ʻo ka ʻaoʻao impeller ka ʻaoʻao hoʻokele, i ka wā e hoʻonui ai ke kinoea e hana i ka hana, ʻo ka ʻāpana ʻōwili ma ka ʻaoʻao impeller i kahi kūlana maikaʻi loa i ka lāʻau bearing ma muli o ka hopena o ka hoʻoheheʻe ʻana i ke kinoea, a mau ka maʻamau o ka ʻaila.I ke kaʻina hana o ka meshing a me ka hoʻouna ʻana i ka torque ma waena o nā mīkini nui a me nā mea liʻiliʻi, me kēia ʻo ka fulcrum, e kaupalena ʻia ka neʻe ʻana o ka ʻaoʻao ʻaoʻao non-impeller ma lalo o nā kūlana overload, a ʻoi aku ka kiʻekiʻe o kāna kaomi lubricating film ma mua o nā mea ʻē aʻe. nā bearings, e hana ana i kēia wahi lubricated Ke piʻi aʻe ka ʻoʻoleʻa kiʻiʻoniʻoni, e emi ana ka nui o ka hoʻololi hou ʻana o ka kiʻiʻoniʻoni aila, a piʻi ka wela frictional, ka hopena i kahi varnish.

3.2.3 ʻO ka varnish i loko o ka ʻaila ka mea nui i hana ʻia i ʻekolu mau ʻano: ʻaila oxidation, ʻaila "micro-combustion", a me ka hoʻokuʻu ʻana i ka wela kiʻekiʻe.Pono ke kumu o ka varnish e ka "micro-combustion" o ka aila.Penei ka mīkini: e hoʻoheheʻe ʻia kekahi nui o ka ea (ma lalo o 8%) i loko o ka aila lubricating.Ke ʻoi aku ka palena o ka solubility, e noho ka ea e komo ana i ka ʻaila i loko o ka ʻaila ma ke ʻano o nā ʻōpū i hoʻokuʻu ʻia.Ma hope o ke komo ʻana i ka bearing, ʻo ke kaomi kiʻekiʻe e hoʻokau i kēia mau ʻōpū i ka hoʻoemi adiabatic wikiwiki, a piʻi wikiwiki ka mahana o ka wai e hoʻoulu i ka "micro-combustion" o ka aila, e hopena i nā insolubles liʻiliʻi loa.He polar kēia mau mea hiki ʻole ke hoʻoheheʻe ʻia a pili i nā ʻili metala e hana i nā varnish.ʻOi aku ka nui o ke kaomi, ʻoi aku ka haʻahaʻa o ka solubility o ka mea hiki ʻole ke hoʻoheheʻe ʻia, a ʻoi aku ka maʻalahi o ka hoʻoheheʻe ʻana a hoʻopaʻa ʻia e hana i kahi varnish.

3.2.4 Me ka hana ana o ka varnish, ka mānoanoa o ka aila kiʻiʻoniʻoni i loko o ka non-free moku'āina i noho 'ia e ka varnish, a ma ka manawa like ka renewal wikiwiki o ka aila kiʻiʻoniʻoni emi iho, a me ka mahana piʻi mālie, e hoʻonui. ʻO ke kuʻekuʻe ma waena o ka ʻili o ka lāʻau hili a me ke kumu, a ʻo ka varnish i waiho ʻia ke kumu o ka hoʻoheheʻe ʻana o ka wela maikaʻi ʻole a me ka piʻi ʻana o ka mahana o ka aila e alakaʻi i ke kiʻekiʻe o ka nahele kumu.I ka hopena, ua hoʻopili ka puke pai i ka varnish, ka mea i hōʻike ʻia i nā loli ikaika i ka haʻalulu o ka shaft.

3.2.5 ʻOiai ʻaʻole kiʻekiʻe ka waiwai o ka MPC o ka aila expander, i ka wā e loaʻa ai kahi varnish i loko o ka ʻōnaehana ʻaila lubricating, ua kaupalena ka dissolution a me ka ua o nā ʻāpana varnish i ka aila ma muli o ka hiki ke hoʻoheheʻe ʻia ka ʻaila lubricating. nā ʻāpana varnish.He ʻōnaehana kaulike dynamic.Ke hiki aku ia i kahi mokuʻāina piha, e kau ka varnish ma luna o ka bearing a i ʻole bearing pad, e hoʻololi i ka wela o ka bearing pad, ʻo ia kahi pilikia huna nui e pili ana i ka hana palekana.Akā, no ka pili ʻana i ka pad bearing, ʻo ia kekahi o nā kumu o ka piʻi ʻana o ka wela o ka bearing pad.

4 Nā ana a me nā mea kū'ē

ʻO ka wehe ʻana i ka hōʻiliʻili ʻana o ka varnish ma ka bearing hiki ke hōʻoia i ka holo ʻana o ka bearing o ka ʻāpana i kahi mahana hoʻomalu.Ma o ka noiʻi a me ka kamaʻilio ʻana me nā mea hana he nui o nā mea hoʻoneʻe varnish, ua koho mākou iā Kunshan Winsonda, nona ka hopena hoʻohana maikaʻi a me ka kaulana o ka mākeke, e hana i ka WVD-II electrostatic adsorption + resin adsorption, ʻo ia kahi mea hoʻohui varnish e wehe i ka pena.membrane.

Hoʻohui maikaʻi nā mea hoʻomaʻemaʻe ʻaila WVD-II i ka ʻenehana hoʻomaʻemaʻe electrostatic adsorption a me ka ʻenehana hoʻololi ion, e hoʻonā i ka varnish i hoʻoheheʻe ʻia ma o resin adsorption, a hoʻonā i ka varnish precipitated ma o electrostatic adsorption.Hiki i kēia ʻenehana ke hoʻohaʻahaʻa i ka ʻike o ka sludge i ka manawa pōkole , I loko o kahi manawa pōkole o kekahi mau lā, hiki ke hoʻihoʻi ʻia ka ʻōnaehana lubrication kumu i loaʻa ka nui o ka sludge / varnish i kahi kūlana hana maikaʻi loa, a me ka pilikia o ka piʻi lohi i loko. Hiki ke hoʻonā ʻia ka mahana o ke kuʻekuʻe i hana ʻia e ka varnish.Hiki iā ia ke hoʻoneʻe a pale i ka ʻaila ʻaila hiki ke hoʻoheheʻe ʻia i ka wā o ka hana maʻamau o ka turbine mahu.

ʻO kāna mau kumu nui penei:

4.1 Ion exchange resin e wehe i ka varnish hemo

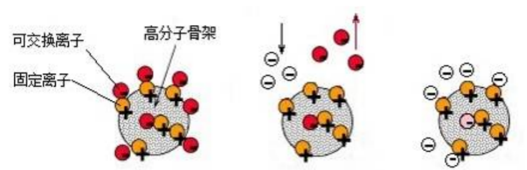

Hoʻokumu nui ʻia ka resin exchange Ion i ʻelua mau ʻāpana: polymer skeleton a me ka hui hoʻololi ion.Hōʻike ʻia ka loina adsorption ma Figure 8,

Kiʻi 8 Kumu o ka ion-interaction resin adsorption

Hoʻokaʻawale ʻia ka hui hoʻololi i kahi ʻāpana paʻa a me kahi ʻāpana neʻe.Hoʻopaʻa ʻia ka ʻāpana paʻa i ka matrix polymer a ʻaʻole hiki ke neʻe manuahi, a lilo i ion paʻa;ʻo ka ʻāpana hoʻoneʻe a me ka ʻāpana paʻa e hui pū ʻia e nā paʻa ionic e lilo i ion hiki ke hoʻololi.ʻO nā ion paʻa a me nā ion mobile he mau kumu kūʻē.Ma ka lāʻau bearing, hoʻoheheʻe ka ʻāpana kelepona i nā ion neʻe manuahi, e hoʻololi me nā huahana degradation ʻē aʻe me ka uku like, i hui pū ai lākou me nā ion paʻa a hoʻopaʻa paʻa ʻia ma ka waihona hoʻololi.Ma ka hui, lawe ia e ka aila, hoʻoheheʻe varnish wehe 'ia e ka ion exchange resin adsorption.

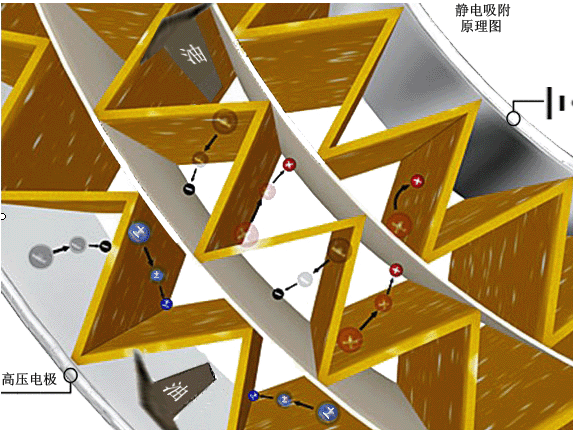

4.2 Electrostatic adsorption ʻenehana e wehe i ka varnish i hoʻokuʻu ʻia

Hoʻohana nui ʻia ka ʻenehana Adsorption Electrostatic i kahi mīkini uila kiʻekiʻe e hana i kahi kahua electrostatic kiʻekiʻe e polarize i nā ʻāpana haumia i loko o ka aila e hōʻike i nā uku maikaʻi a maikaʻi ʻole.Hoʻopiʻi ʻia nā ʻāpana kūʻokoʻa a hoʻoneʻe ʻia e nā ʻāpana i hoʻopiʻi ʻia, a ʻo ka hope ua hoʻopili ʻia nā ʻāpana āpau a hoʻopili ʻia i ka ʻohi (e nānā i ke Kiʻi 9).

Kiʻi 8 Kumu o ka ʻenehana adsorption electrostatic

Hiki i ka ʻenehana hoʻomaʻemaʻe ʻaila electrostatic ke hoʻopau i nā mea haumia ʻole a pau, e komo pū me nā mea ʻalaʻala a me ka varnish i hoʻokuʻu ʻia i hana ʻia e ka ʻaila degradation.Eia nō naʻe, hiki i nā mea kānana kuʻuna ke wehe i nā ʻāpana nui me ka pololei kūpono, a paʻakikī ke wehe i ka submicron pae varnish suspended .

Hiki i kēia ʻōnaehana ke hoʻopau piha i ka varnish precipitated a waiho ʻia ma luna o ka pad bearing, a laila e hoʻopau piha i ka mana o ka wela o ka bearing pad a me nā loli vibration i hana ʻia e ka varnish, i hiki ai i ka hui ke holo paʻa no ka manawa lōʻihi.

5 Ka hopena

Ua hoʻohana ʻia ʻo WSD WVD-II varnish removal unit, ma o ʻelua mau makahiki o ka nānā ʻana i ka hana, ua mālama mau ʻia ka mahana wela ma kahi o 90 ° C, a ua mau ka ʻāpana i ka hana maʻamau.Ua loaʻa kahi kiʻiʻoniʻoni varnish (e nānā i ke kiʻi 10).

ʻO ke kiʻi kino o ka hoʻokaʻawale ʻana ma hope o ke kau ʻana i ka varnish wehe

mea lako

nā kuhikuhi:

[1] Liu Siyong, Xiao Zhonghui, Yan Zhiyong, and Chen Zhujie .ʻO ka hoʻohālikelike helu a me ka noiʻi hoʻokolohua e pili ana i nā hiʻohiʻona ikaika o ka pivot elastic a me ka damping tilting pad bearings [J].Ka Nupepa Pākē o ka ʻenekinia ʻenehana, ʻOkakopa 2014, 50(19):88.

Ka manawa hoʻouna: Dec-13-2022